The Joris Laarman Lab, located in Amsterdam, is known for experimenting and tinkering with the new possibilities of upcoming technology alongside craftspeople, scientists and engineers. Their latest feat includes a technique for large-scale 3D printing of 3D objects made from steel, stainless steel, aluminum, bronze or copper on any work surface that does not require any additional support structures. “The MX3D-Metal method combines a robotic arm typically used in car manufacturing with a welding machine to melt and then deposit metal, to create lines that can be printed horizontally, vertically, or in curves without the need for support structures.”

Back in 2010 we wrote about Joris Laarman’s solo exhibition in New York featuring ‘bone chairs’.

Watch the video to see how it is possible to create metal structures in mid-air, as it has something quite magical to it.

(Links: phys.org, www.dezeen.com, Photo of freeform metal lines from dezeen.com)

A company called 3DSVP will start offering 3D printing services on the premises of the Meneer Paprika store in Haarlem next January,

A company called 3DSVP will start offering 3D printing services on the premises of the Meneer Paprika store in Haarlem next January,  Kees is a Dutch online company that lets you customize and 3D print iPhone cases based on a large number of presets.

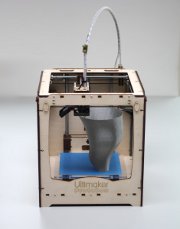

Kees is a Dutch online company that lets you customize and 3D print iPhone cases based on a large number of presets. Three guys who met at the Fab Lab in Utrecht two years ago decided to go into business together as manufacturers of a 3D printer. The resulting

Three guys who met at the Fab Lab in Utrecht two years ago decided to go into business together as manufacturers of a 3D printer. The resulting